Problem: Gearbox Mount & Coupling Loose

Machine: 75 hp Mix Chest Paddle Wheel

Solutions: VibePro 24/7 Permanent Mount Vibration Monitoring

Executive Summary

This case study demonstrates the critical role of VibePro’s 24/7 permanent monitoring system in identifying and mitigating a significant risk within a mix chest paddle wheel system. Through advanced vibration analysis, the monitoring technology detected issues related to the gearbox mounting and coupling, leading to a tailored intervention that not only resolved the underlying problem but also resulted in considerable cost savings.

Initial Observations

The mix chest paddle wheel, an essential component powered by a 75 hp 1775 rpm 480 volt AC WEG motor, rolling element bearings, driving a single (1) reduction Falk gearbox presented recurring issues that were initially elusive. VibePro’s vibration analysis pinpointed the core problem: looseness in the gearbox mounting and coupling. Despite multiple maintenance attempts throughout the year, the issue persisted due to an oversight in the compatibility of bolt lengths and hole sizes within the mounting setup.

Onsite Analysis

The diagnosis revealed that the frequencies of interest were directly associated with the looseness in the gearbox’s mounting and coupling. This setup involved the gearbox being attached to a plate, which then mounted to a larger base plate, integrating the whole motor/gearbox assembly. Repeated maintenance efforts had failed to permanently resolve the issue, as hold-down bolts consistently loosened over time, leading to further instability.

Corrective Action

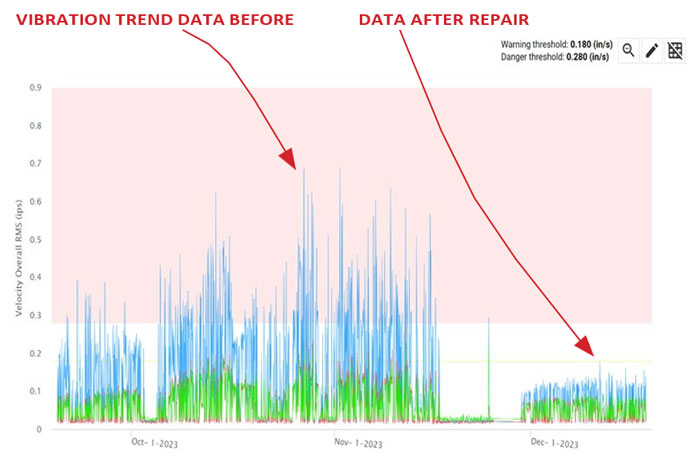

Upon discovering the mismatch between the bolt lengths and the holes in the base, the recommendation was made to install a new, thicker mounting base with correctly sized holes and bolts, ensuring a secure and stable assembly. Continuous monitoring was advised to safeguard against future issues.

Cost Saving Analysis

The proactive resolution of this issue prevented potential downtime that could have resulted from a complete gearbox failure, with the cost of avoided downtime estimated at $7,500 (3 hours at $2,500 per hour). The total cost for labor and parts in addressing the problem was $896, compared to the potential unplanned maintenance costs of $9,492. This strategic intervention saved an estimated $8,596, highlighting the financial benefits of proactive maintenance facilitated by VibePro’s monitoring system.

Future Focused Solutions

This case underscores the value of integrating continuous monitoring technologies in maintenance strategies to identify and rectify potential failures before they escalate into costly repairs or operational downtime. VibePro’s system not only supports the immediate identification of mechanical instabilities but also fosters an environment of preventative maintenance, ultimately contributing to more reliable and cost-effective operations.