Problem: Inconsistent Cutting Quality

Machine: Multi-blade Industrial Saw

Solution: VibePro Vibration Analysis

Executive Summary

Executive Summary

In a breakthrough application of VibePro’s 24/7 continuous vibration and temperature monitoring technology, a significant issue with production line spindles was identified and rectified. This case study highlights how the VibePro system’s alerts led to the discovery of spindles operating far beyond the ISO balance specifications, ultimately preventing potential equipment failure and ensuring uninterrupted production.

Initial Observations

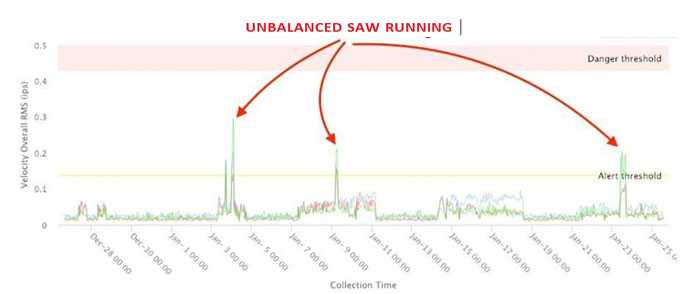

The pivotal moment came when VibePro’s monitoring system repeatedly triggered alarms over several months. These sporadic alerts, initially puzzling, were linked to specific production saw spindles. Notably, these alarms were inconsistent, only occurring when certain saws, later termed “Bad Actors,” were operational. This intermittent pattern was a key indicator in pinpointing the root cause.

The VibePro mounted sensor detected the inconsistent anomaly that might have been missed with routine measurements as shown in the chart below:

Onsite Analysis

Our team conducted an onsite inspection, focusing on the balance of the rotating equipment. By activating the vibration and temperature sensors remotely, we established that the cutting process itself did not exacerbate the vibration issue. Further investigation revealed a critical imbalance in certain spindles, while others functioned normally. Three primary factors were identified:

The spindle size was insufficient for the blade’s weight, making it prone to imbalance.

The spindle size was insufficient for the blade’s weight, making it prone to imbalance.- Absence of balance correction marks on the blades, indicating a potential oversight in quality assurance from the OEM (Original Equipment Manufacturer).

- The stacking of three or more blades on each spindle, a design choice that significantly increased the risk of imbalance.

Corrective Action

Our analysis showed that the imbalanced saws generated excessive vibration, risking premature bearing failure, spindle shaft and housing wear, and damage to other machine components. Some blades registered vibrations as high as 0.50 in/sec, over 12 times the acceptable level.

To address these issues, we recommended:

To address these issues, we recommended:

- Testing and balancing a new blade and spindle with VibePro.

- Engaging with the blade OEM to enhance their balancing procedures, ensuring quality

- Balancing the out-of-tolerance blades during the next scheduled production shutdown to bring them within acceptable vibration levels.

Future-Focused Solutions

VibePro is now collaborating with the client and the OEM to establish a long-term strategy for pre-balancing saw blades. While VibePro offers balancing expertise, we believe in empowering the OEM to integrate these best practices into their manufacturing process. This proactive approach ensures quality and reliability right from the start, significantly reducing the risk of future equipment issues.

Executive Summary

Executive Summary The spindle size was insufficient for the blade’s weight, making it prone to imbalance.

The spindle size was insufficient for the blade’s weight, making it prone to imbalance.