We’ve said it before, and we’ll say it again: unplanned downtime can significantly impact a company’s bottom line. This is where predictive maintenance comes in, offering a proactive approach to equipment maintenance that can save both time and money. At the heart of every modern predictive maintenance program are machine analysis tools. Today, we’ll look further into predictive maintenance, its key components, its history, and the technology that fuels it.

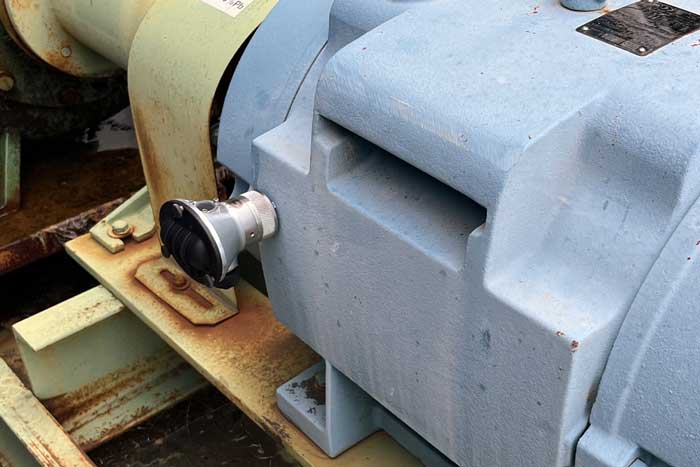

Let’s start with some predictive maintenance applications. While it can be used on many types of equipment, it’s particularly effective for rotating machinery such as pumps, air coolers, mixers, compressors, turbines, motors, spindles, gearboxes, and others. These machines play critical roles in production processes, making their reliability essential.

Understanding Predictive Maintenance

Predictive maintenance uses data-driven insights to predict when equipment is likely to fail, allowing maintenance to be performed before it’s needed. This approach offers several advantages over traditional maintenance methods:

- Reduced downtime

- Lower maintenance costs

- Extended equipment lifespan

- Improved safety

- Avoid replacements

The value of predictive maintenance lies in its ability to prevent unexpected failures, optimize maintenance schedules, and maximize equipment performance and efficiency.

Components of a Predictive Maintenance Program

A comprehensive predictive maintenance program consists of several key components including the maintenance plan, skilled personnel, and most importantly, the hardware and software that collects the data, and makes it available for analysis. Let’s take a closer look at each component:

- Maintenance Plan – this is the strategic plan that outlines goals, procedures, responsibilities and scheduling. A list of equipment in order of most critical to lowest provides a good roadmap on which equipment to focus on first.

- Hardware – Sensors and data collection devices.

- Software – Advanced analytics platforms that process and interpret the machine data.

- Skilled Personnel / Partners – Trained technicians and analysts to implement the program, analyze data, and determine required actions in response to what’s uncovered. Companies have the option to contract out analysis services or to perform them in house. Working with a reliable third-party allows companies, typically smaller to mid-sized ones and sometimes larger ones, access to talent and ability to scale without having to employ technicians full time.

Predictive Maintenance Tools and Functions

Various tools and sensors are employed in predictive maintenance, each focusing on its own set of parameters to assess equipment health. Here are the key components, and their role within the system:

| Vibration Sensors/Accelerometers | Vibration is often the first indicator of mechanical issues. Sensors/accelerometers detect and measure vibration patterns. This is especially valuable since vibration is often inaudible to the human ear, and once it can be heard, it’s often too late to avoid costly repairs and replacements. |

| Temperature Sensors | Increases in temperature can signal friction problems, electrical issues and other problems within the system. |

| Ultrasonic Sensors | Abnormal noises can indicate internal problems. These sensors detect high-frequency sounds, also often inaudible to the human ear, indicating issues. |

| Infrared Cameras | Identify hot spots and thermal anomalies. |

| Oil Analysis Tools | Low levels of oil, or contaminated oil, can lead to bearing failure, and other mechanical headaches. Oil analysis reveals wear patterns and contamination. If caught early enough, catastrophes can be avoided. |

| Alignment Tools | Alignment tools help keep key components in alignment which reduces component wear, minimizes vibration, and helps improve energy efficiency. They also extend equipment lifespan, enhance safety, and lower maintenance costs. Proper alignment helps ensures better product quality. |

| Balancing Equipment | Proper balance is crucial for rotating equipment performance. Balance equipment will help ensure proper balance and reliable operation. |

Note: This table contains the primary predictive tools and functions, but know that others may be used to monitor attributes such as power quality or pressure (for hydraulic/pneumatic systems), among others.

Approaches to Data Collection

There are two primary approaches to implementing predictive maintenance: route based and permanent solutions. With route based, technicians periodically collect data using portable devices, following predetermined routes to equipment throughout the facility. This method is flexible but labor-intensive. With permanent solutions, sensors are permanently installed on critical equipment, providing continuous monitoring. While more expensive initially, this approach offers real-time insights and is generally more cost-effective in the long run. The choice between these approaches depends on factors such as equipment criticality, budget constraints, and available resources.

> To learn more about the differences between route based and permanent machine monitoring, please check out this blog.

Historical Context: From Preventive to Predictive Maintenance

To fully appreciate the value of predictive maintenance, it’s helpful to understand its evolution. Traditionally, maintenance was performed on a fixed schedule, regardless of the equipment’s actual condition. This approach, while better than reactive maintenance, often led to unnecessary maintenance activities and didn’t prevent all unexpected failures.

As technology evolved, so did predictive maintenance. By leveraging data and advanced analytics, predictive maintenance allows for more precise and timely interventions. This shift from time-based to condition-based maintenance represents a significant advancement in asset management strategies.

The History of VibePro

While we generally don’t like to brag, we are proud to say that when initially released, VibePro was a huge industry disrupter. It was the first tablet-based vibration analyzer on the market – available within two months of the iPad being released! Before VibePro, quality and reliability teams used industry-specific analyzer bots and balancers. As with many breakthrough innovations, the predictive industry turned their back at first to VibePro’s approach. However, once they understood the power and benefits of the technology, suddenly others were playing catch up. Meanwhile, VibePro continued to lead the space, incorporating the Internet/cloud, cameras, GPS and other technologies to improve the process.

Innovation remains at the core of VibePro who still leads the industry, offering several key differentiators and newer features such as:

- It’s a true all-in-one solution, presently offering over 100 diagnostic tools. Besides vibration analysis, it handles balancing, alignment, thermography and ultrasound sensing for leaks and lubrication monitoring, and so much more.

- VibePro is the only solution that acts as both a walkaround vibration analyzer allowing for route data uploads in conjunction with permanently mounted sensors. Data flows into one system, allowing for much more efficient analysis, and better-informed action planning.

- Robust data-rich dashboards and user-friendly info graphics, able to display vibration data in many forms.

The Impact of Technology

Predictive maintenance in its present form could not exist without many advances in technology. The Internet of Things (IoT) allows for deployment of connected sensors. Big data analytics provides the ability to process and interpret vast amounts of data. Cloud computing provides scalable storage and processing, with on-demand access worldwide. These technologies have transformed maintenance from a reactive necessity to a proactive strategy that contributes to overall operational excellence.

However, the ability to accurately analyze machine performance relies on another key factor: the ability to communicate accurate data, in real time, with extremely high fidelity. To achieve this, VibePro utilizes proprietary wireless technology. It’s faster than Bluetooth and other protocols, doesn’t interfere with other channels, and can’t be hacked by WiFi.

Predictive Maintenance: Now and in the Future

Machine analysis tools play a central role in modern predictive maintenance programs. By providing insights into equipment health and performance, these tools enable manufacturers to move from reactive to proactive maintenance strategies. As technology continues to advance, so will the capabilities of predictive maintenance, offering even greater potential for operational efficiency and cost savings.

Embracing predictive maintenance and investing in the right machine analysis tools can give organizations a competitive edge in today’s data-driven industrial landscape. As we look to the future, the integration of artificial intelligence and machine learning promises to make predictive maintenance even more powerful, paving the way for truly smart factories and highly optimized operations.

> Have a question about machine analysis tools or predictive maintenance? Contact us here!