We talk to a lot of people about predictive analysis, for obvious reasons.

In our conversations, we see that there are still a great deal of owners and operators who are reluctant to make the investment. One particular comment we hear is that people prefer to use their own “naked ear” to know when machinery needs work.

While our ears are important tools — we’d never claim otherwise — they’re more of a “last line of defense” tool than a front-line tool. If you can hear something wrong in your equipment, you’re already too late to avoid costly repairs or replacement. Damage was done long before you could hear it happening.

This is the crux of what people misunderstand about predictive analysis: They know that there is an upfront cost to installing a predictive analysis solution but zero cost for their own senses. They fail to consider all of the capabilities of a predictive analysis solution and the considerable reductions in repair costs, not to mention unplanned downtime, that such a solution provides.

The Value of Data

The key to developing a full understanding of predictive analysis is understanding the value of data. After all, the collection and analysis of data is the primary purpose of predictive analysis solutions.

The key to developing a full understanding of predictive analysis is understanding the value of data. After all, the collection and analysis of data is the primary purpose of predictive analysis solutions.

Predictive analysis utilizes a variety of testing methods to collect informative data. These include vibration analysis, thermography and ultrasound. Let’s focus on the big one: vibration analysis. Not only are vibrations the most common indications of stress in CNC machining processes, but they also can represent the most damaging threats.

How do data and vibrations relate to each other? Well, another word for “vibration” would be “frequency”. Basically, vibrations become sound. And just like when humans make sounds with our larynxes to share information — or data — with each other, your equipment’s vibrations are sharing data with you.

Unfortunately, no matter how finely tuned your ear is, you’re physically limited in regards to the range of vibration that you can perceive. A vibration detection and analysis system, on the other hand, can perceive them far sooner than humans can — and alert you to the changes before it’s too late.

What Vibration Analysis Does

Of course, it tells you how your machinery is vibrating. But a well-designed system will tell you what’s vibrating, how, even why — and it can give you important clues to the failures that these vibrations can lead to.

Some of the conditions that vibration monitoring can reveal include:

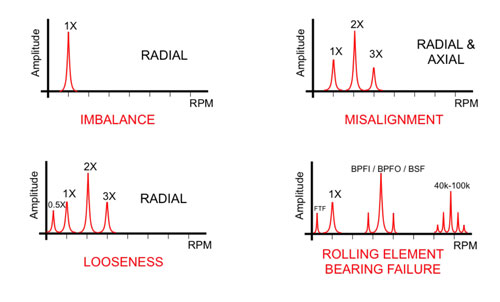

Bearing/rolling element health — Bearing failure is a natural phenomenon; vibration monitoring makes tracking bearing lifecycle simple, eliminating surprise failures when done properly

Bearing/rolling element health — Bearing failure is a natural phenomenon; vibration monitoring makes tracking bearing lifecycle simple, eliminating surprise failures when done properly

Imbalance — Often a tooling issue, but could be something else, such as a dirty fan blade, for instance

Misalignment — Shafts that are out of alignment put strain on rotating machines, resulting in a loss of power transmission as well as damage to, and even failure of, the bearings, couplings, and other associated components.

Looseness — Looseness in your equipment manifests as vibratory sub-harmonic frequencies

Mechanical wear — Can occur in couplings, bearings, support structures, etc.

Other — machine drive issues, lubrication issues, soft foot, broken rotor bars, pump cavitation, etc.

Each of these problems causes different vibrations and, as you use and learn a vibration monitoring system, you’ll learn to spot the signs of each. Over time, the goal is to correlate what you see in the data with what’s specifically happening within the machine.

Understanding the Data

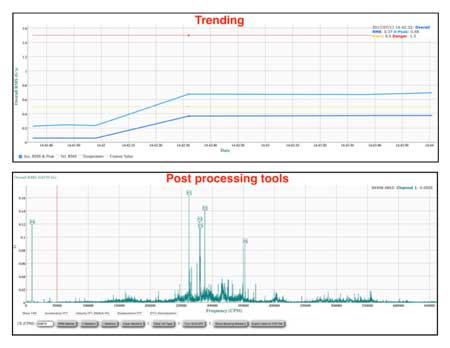

It can seem intimidating to suddenly have access to all this data, especially before you’ve gotten a handle on how to interpret it. If you implement a high-quality predictive analysis system, however, the software component will help with the interpretation.

Even if you use a system like this at its most basic — one measurement taken periodically — you’re going to see a benefit. After all, as they say, three pieces of data is a trend, and a trend is my friend. It gives you something to evaluate and compare over time.

The point is that if you are serious about reducing repair and maintenance costs, and about minimizing unplanned downtime, doing the old ear check isn’t going to cut it. You need a robust set of data — and predictive analysis is the best way to get it.